I-D133*L1980 i-silicone yokususa uthuli lwamathambo

Incazelo Yomkhiqizo

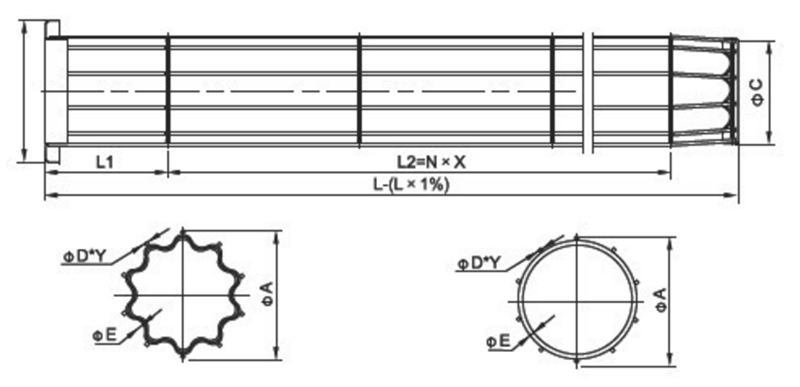

Njengombambo wesihlungi sesikhwama, ifreyimu yokususa uthuli kulula ukuyifaka nokuvikela, ngakho-ke abantu bavame ukuyiziba lapho besebenzisa futhi behlola isihlungi sesikhwama.Kodwa ikhwalithi yohlaka lokukhipha uthuli luthinta ngqo impilo yesevisi yesihlungi sesikhwama.Ngakho-ke, lapho uhlola uhlaka lokususa uthuli, kunamaphuzu amaningana ayisihluthulelo okufanele unake: kungakhathaliseki ukuthi uhlaka lokususa uthuli lufakwe ngokugcwele ekubumbeni okulodwa, bushelelezi futhi luqinile, ngaphandle kwama-burrs, ukuze isikhwama sokuhlunga singalimazi, ukushisela umfaniswano, futhi isakhiwo sinengqondo.Imangelengele futhi ihlala isikhathi eside.Uhlaka lwe-trapezoidal luthatha isakhiwo esiyisicaba.Izimbambo ze-longitudinal kanye nezindandatho eziphikisana nokusekela ze-trapezoidal skeleton zisakazwa ngokulinganayo, futhi zinamandla anele okugwema ukulimala nokuguqulwa.Ukuze siqinisekise amandla ocingo lwensimbi futhi sithuthukise ikhwalithi yokubukeka, sikhetha u-φ6.5 yuan Insimbi idonswa (idonswa ku-φ3mm), bese kuthi lapho isihlanganiswe ethayini elishiselwe ezinqeni, izoba phansi ukuze ihlangane. izidingo zamakhono.Uhlaka lwe-trapezoidal lwenziwe ngokufafaza kwe-silicon ephilayo noma i-galvanizing, ukupenda kwesifutho namanye amakhono.I-coating inamandla futhi imelana nokugqwala, okugwema ukugqwala kwethambo lekheji kanye nokunamathela kwesikhwama sokuhlunga ngemva kokusebenza komqoqi wothuli isikhathi esithile.

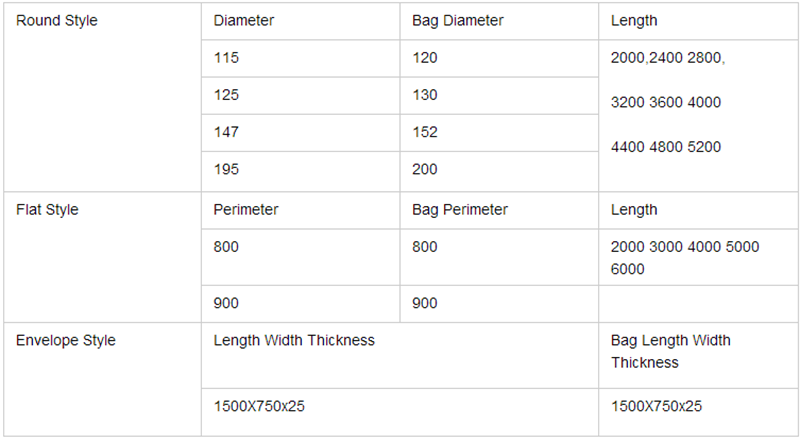

Ipharamitha yobuchwepheshe

Bonisa imininingwane

1. Ikhwalithi yensimbi yensimbi, ebushelelezi ngaphandle kwama-burrs

2. I-plating layer iqinile futhi ayigqwali, futhi kulula ukushintshwa kwesikhwama sendwangu

3. Izihlanganisi ze-solder ziqinile, ngaphandle kokuchithwa, ukulahleka kwe-solder nokuphuka

4. Idizayini eyindilinga enezimbambo eziningi, ukusekela okuqinile ukuvimbela ukulimala nokuguqulwa

Iphakhejig