Ikheji lesihlungi sensimbi engagqwali yokususa uthuli

Uhlaka lokususa uthuli lwensimbi engagqwaliikheji lokuhlunga

Incazelo Yomkhiqizo

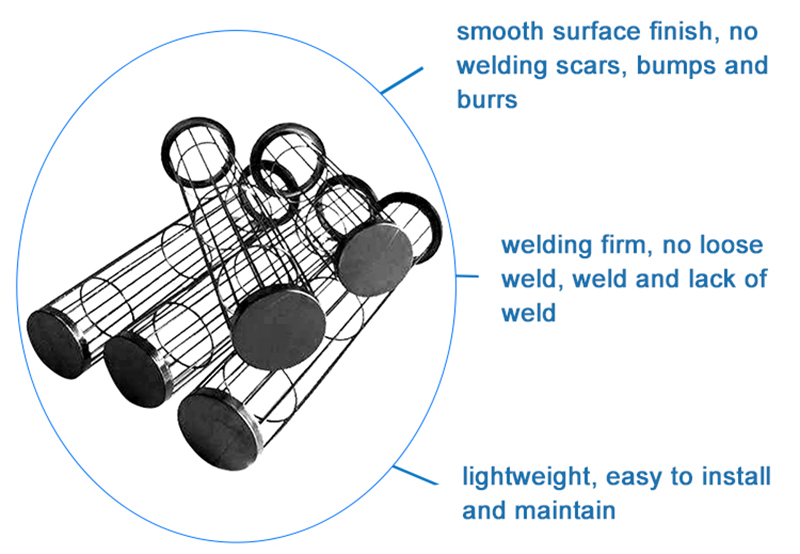

Uhlaka lokususa uthuli lwensimbi engenasici lunamandla anele, ukuqina, ukuma kanye nokunemba kwe-dimensional ukuvimbela ukuwohloka ngaphansi kokucindezelwa, ukulimala ngesikhathi sokuthutha, ukuthintana ngemva kokuba isikhwama sokuhlunga uthuli sifakwe kumqoqi wothuli, ubunzima bokufaka isikhwama, kanye nokungqubuzana phakathi uhlaka lwesikhwama, njll.Ingaphezulu lohlaka lokususa insimbi engagqwali liphathwe nge-anti-corrosion.

Uhlaka lokususa uthuli lwensimbi engagqwali lusetshenziswa kakhulu abaqoqi bothuli.Uma singekho isikhala esanele sokufaka ifreyimu yokususa uthuli, kudingeka uxhumano lwamakhanda amaningi.Izici eziyinhloko zohlaka lokususa uthuli lwensimbi engagqwali wukushisela okuqinile, ukubukeka okubushelelezi nokuqondile, futhi awekho ama-burrs.Imininingwane ephelele ingenziwa ngezifiso ngokuya ngezidingo zekhasimende.

Uhlaka lokususa uthuli lwensimbi engenasici luwubambo lwesikhwama sokuhlunga.Kufanele kube lula futhi kube lula ukuyifaka nokuyinakekela.Ikhwalithi yohlaka ithinta ngokuqondile isimo sokuhlunga kanye nempilo yesevisi yesikhwama sokuhlunga.Sebenzisa intambo yensimbi noma insimbi engagqwali enamandla anele kanye nokuqina, uthayela, ufuthwe, futhi umbozwe nge-organic silicon.Uhlaka lokususa uthuli olucutshungulwe yinkampani yethu lisebenzisa ubuchwepheshe be-organic silicon lungangena esikhundleni ngokuphelele uhlaka lwensimbi engagqwali, olunganciphisa kakhulu izindleko zokulungisa izinto zokusebenza.Futhi yonke ifreyimu ekhiqizwayo ingahlangabezana nezidingo zokukhanya, ukushelela nokuqondile ngaphandle kwama-burrs.Umthamo wokukhiqiza wonyaka ufinyelela izingcezu eziyizigidi ezimbalwa, ezingahlangabezana nezidingo eziphuthumayo zokuhlinzekwa kwamakhasimende.

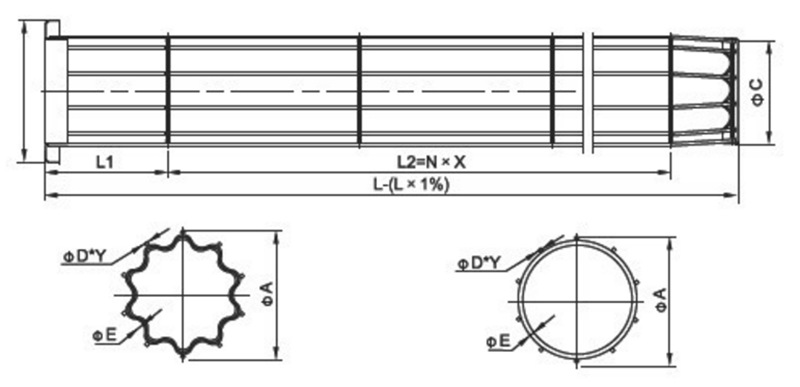

Ipharamitha yobuchwepheshe

Bonisa imininingwane

1. Ikhwalithi yensimbi yensimbi, ebushelelezi ngaphandle kwama-burrs

2. I-plating layer iqinile futhi ayigqwali, futhi kulula ukushintshwa kwesikhwama sendwangu

3. Izihlanganisi ze-solder ziqinile, ngaphandle kokuchithwa, ukulahleka kwe-solder nokuphuka

4. Idizayini eyindilinga enezimbambo eziningi, ukusekela okuqinile ukuvimbela ukulimala nokuguqulwa

Ukupakisha nokuthunyelwa