Ikheji Yesihlungi Sesikhwama Sothuli Esesezingeni Eliphezulu

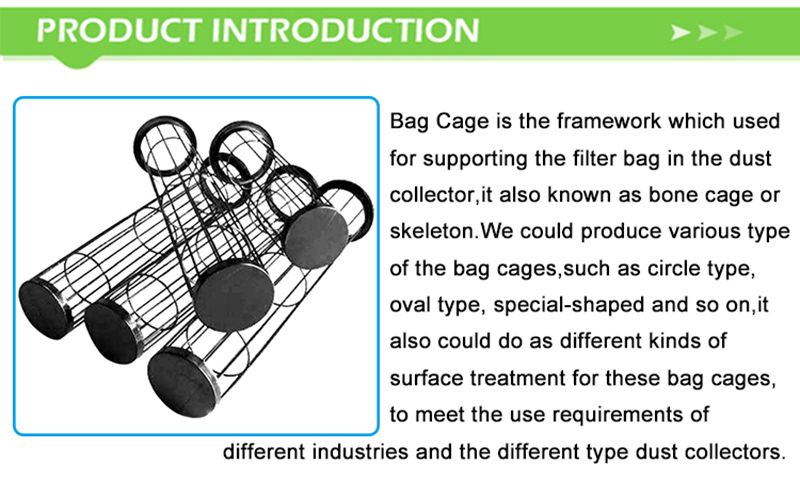

Uhlaka luyi-"rb" yesikhwama sokuhlunga.Sishiselwa kanye ngemishini yokushisela okuzenzakalelayo.i-welding iqinile futhi ibonakala ibushelelezi futhi iqondile, ukuze isikhwama sokuhlunga singonakali.Silula futhi kulula ukusifaka futhi I-maintenance.I-zinc plating noma inqubo yokufafaza ngepulasitiki isetshenziselwa ukwelapha ngemuva kokwelashwa.

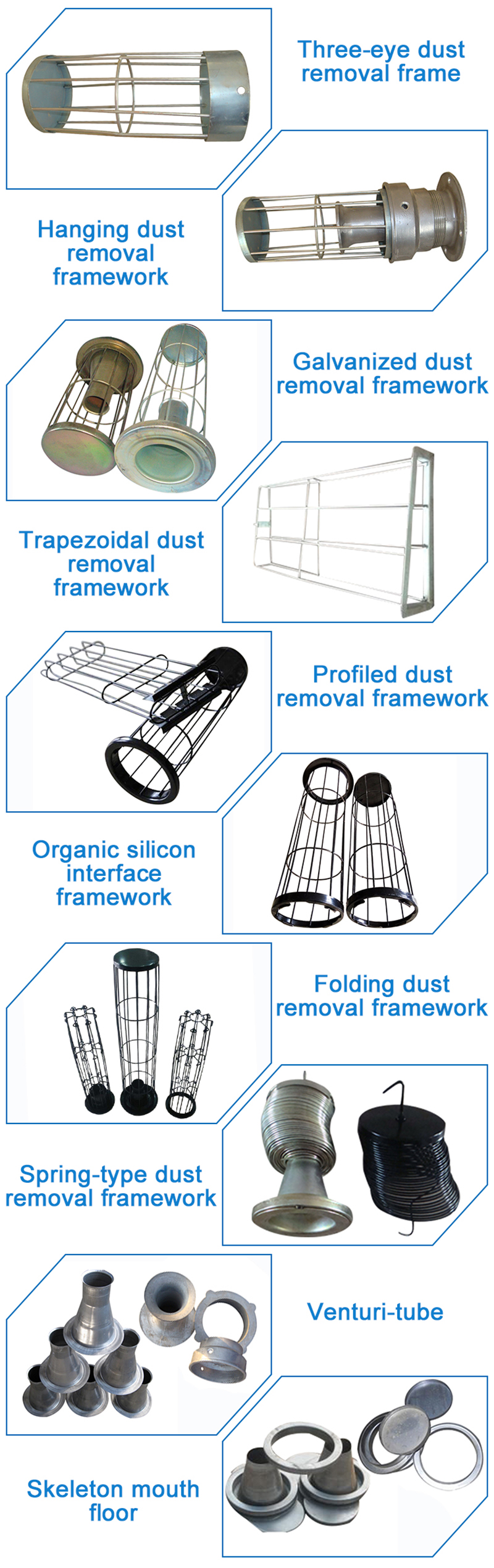

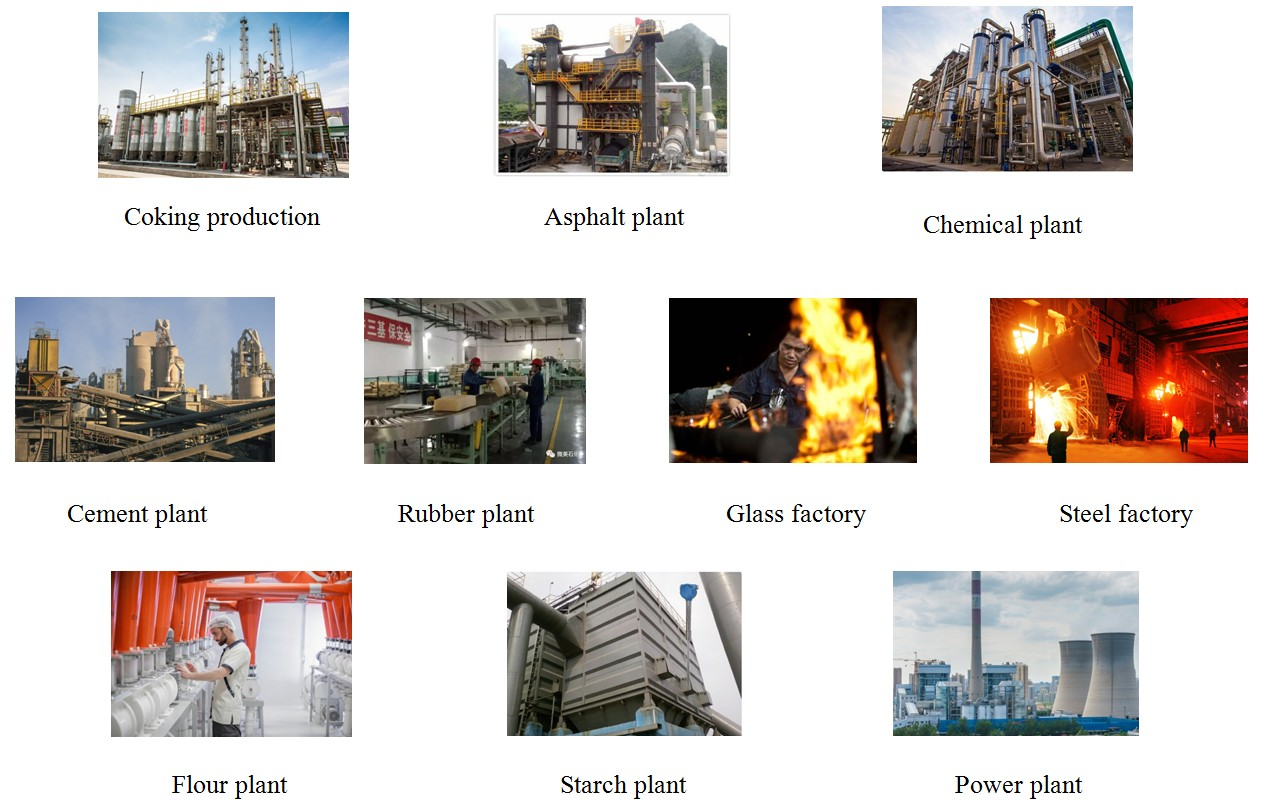

Uhlaka lokususa uthuli lungenye yezesekeli ezibalulekile zesikhwama sendwangu esikhipha uthuli.Ingahambisana nezinsimbi eziyisithupha, eziyisishiyagalombili, eziyishumi, eziyishumi nambili, eziyishumi nesithupha, eziyishumi nesishiyagalombili, ezingamashumi amabili, ezingamashumi amabili nane.Iqhaza lohlaka lokususa uthuli likhulu kakhulu, futhi izinga lesikhwama lithinta kakhulu impilo yaso yokusebenza.Sisetshenziswa kabanzi kwezensimbi, embonini yamakhemikhali, ekuphekeni, ekuphehleni ugesi, ekuncibilikiseni okungeyona insimbi, insimbi nensimbi, izinto zokwakha, amalahle. izimayini nezinye izimboni.

Uhlaka lohlaka lwamathambo luwubambo lwesikhwama sokuhlunga.Kufanele kube lula futhi kube lula ukuyifaka nokuyinakekela.Izinga lefreyimu lithinta ngokuqondile isimo sokuhlunga kanye nempilo yesevisi yesikhwama sokuhlunga. Yamukela i-granite yemvelo, ngemva kokucutshungulwa ngomshini ibe yingcwecwe yokugoba eyindilinga, isakhiwo sonke sibushelelezi futhi sibushelelezi.Ayikwazi ukumelana nokuguguleka, ukuguga kanye nokushisa okuphezulu.Ngaphandle insimbi enamandla aphezulu ekwazi ukumelana nokushisa kanye nezinto ezikwazi ukumelana ne-alkali.Insimbi yangaphandle yensimbi yesilinda ithuthukisa kakhulu amandla nempilo yesevisi yemishini.Umzimba wamukela ukwakheka kwemitha elingu-1 esigabeni ngasinye, futhi ilunga ngalinye linamalungu ayi-concave kanye ne-convex. .Ngesikhathi sokufakwa, i-furan resin noma usimende ongamelana ne-asidi kanye ne-alkali isetshenziselwa ukuxhuma amalunga ukuze kuqinisekiswe ukuthi amalunga awavuzi.Nqoba izinkinga ezivamile zokugeleza kwamanzi nokuvuza komoya emalungeni omqoqi wothuli we-granite wokuqala.Ithangi lamanzi eliphezulu. iyisakhiwo se-ceramic, futhi umqoqi wothuli lwe-ceramic uqinisekisa ukuthi akukho ukuvuza kwamanzi ngesikhathi sokuhlinzekwa kwamanzi, okugwema ukukhungatheka kokugeleza kwamanzi ethangini lamanzi lomqoqi wothuli we-granite wokuqala futhi kuthuthukise umphumela wokusetshenziswa komqoqi wothuli.Ukufakwa ilula, ngokuvamile ingxenye ngayinye iyimitha elingu-1, futhi ukuphakanyiswa kwendawo kungaqedwa ngesigamu sosuku, ukunciphisa umjikelezo wokwakha.

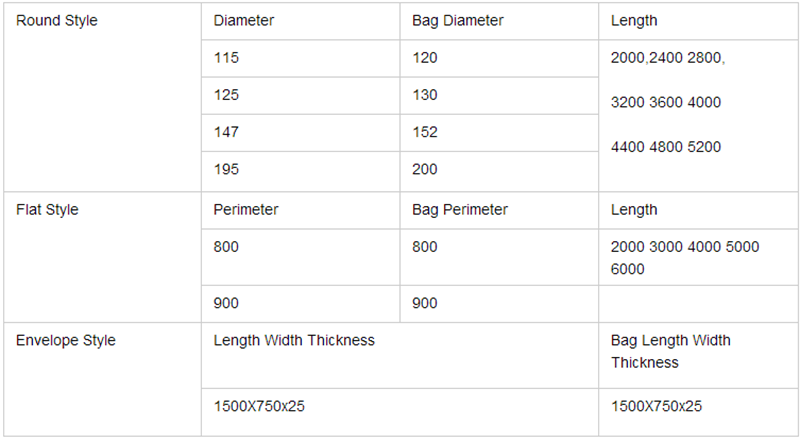

Ipharamitha yobuchwepheshe

Bonisa imininingwane

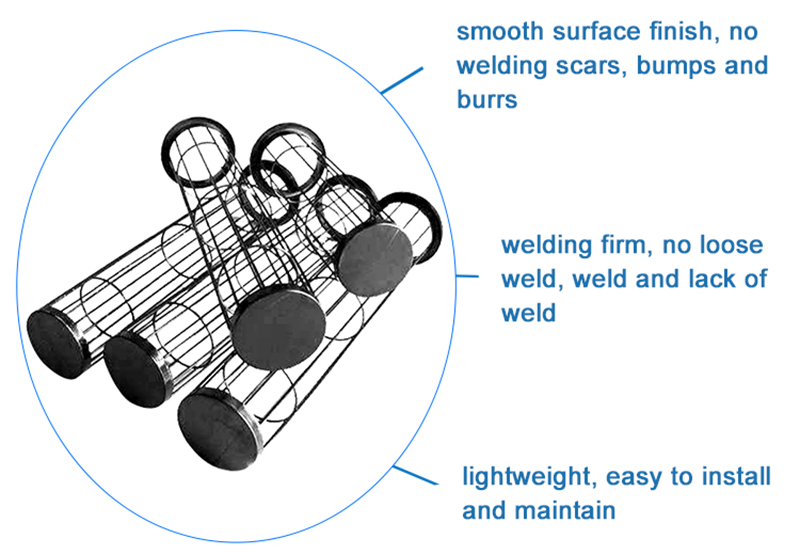

1. Ikhwalithi yensimbi yensimbi, ebushelelezi ngaphandle kwama-burrs

2. I-plating layer iqinile futhi ayigqwali, futhi kulula ukushintshwa kwesikhwama sendwangu

3. Izihlanganisi ze-solder ziqinile, ngaphandle kokuchithwa, ukulahleka kwe-solder nokuphuka

4. Idizayini eyindilinga enezimbambo eziningi, ukusekela okuqinile ukuvimbela ukulimala nokuguqulwa

Isicelo

Ukupakisha kanye Nokuthumela